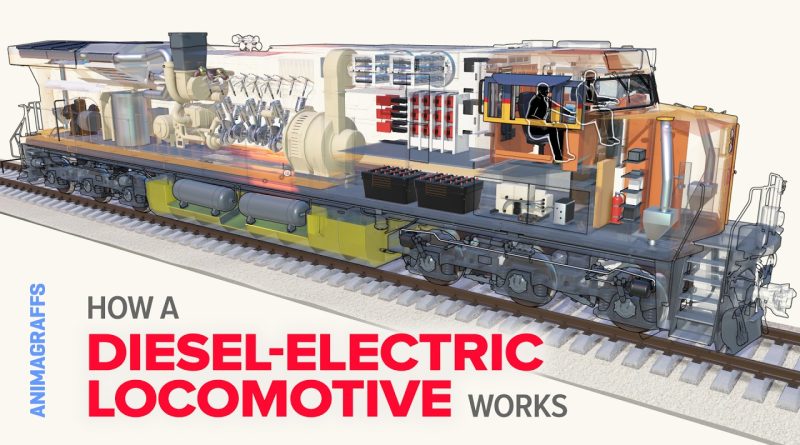

How a Diesel-Electric Locomotive Works

Peer deep into the workings of a heavy-haul freight locomotive, rendered in full 3D!

CREDITS

Jacob O’Neal – Modeling, animation, texturing, vfx, music, narrative script

Wesley O’Neal – Research, technical script

MUSIC

I composed the background music specifically for this video. Hear “Locomotion” on my Soundcloud:

PATREON

Help us keep making videos:

https://www.patreon.com/animagraffs

PRIVATE WORK

Need 3D illustration and animation? Let’s chat:

WEBSITE

See more explanations of how things work:

https://animagraffs.com/

SOFTWARE USED

We use Blender 3D to create these models. It’s free and open source, and the community is amazing:

0:00 Intro

00:31 Body and frame

02:38 Coupling

04:14 Draft gear

04:58 Coupling cables

05:40 Engine

06:38 Turbocharging

08:31 Exhaust gas recirculation system (EGR)

09:06 Water

10:12 Electrical

10:31 Traction motors

12:02 Batteries

12:22 Trucks / bogies

14:30 Sand system

15:06 Braking

15:21 Pneumatic brake system

17:02 Dynamic braking system

19:00 Nose / Operator’s cab

20:13 Operator controls

23:09 Engine control panel

24:06 Crew member’s area

24:37 Final tour

Correction:

0:10 Before commenting, check the top pinned “VIDEO CORRECTIONS” thread.

how to repair windows 7

VIDEO CORRECTIONS (complied from viewer comments):

For questions about fuel usage calculations:

https://www.factcheck.org/2008/07/fuel-efficient-freight-trains/

From user @briancelidonia8258:

Some corrections (some nit-picky and some significant, mostly nitpicky):

00:00 Front door opens the other way on newer locomotives. This is in case the loco falls on over on the right side (blocking the rear exit door), the front door will flop open, allowing the crew to climb out without having to lift the door.

00:05 The small cranking transfer box shown on the left walkway has been removed for 10 years. (not mentioned in the description)

05:25 The "dummy" recepticle is shown having pins. The dummy doesn't have pins, that's why it is the dummy.

10:27 The Alternator Blower cooling air then cools the rectifier and inverters before exiting the loco. It does not just cool the alternator.

11:24 Only 4 inverter are shown on a 6 motor locomotive.

11:38 "This process may change". Not sure why it would. Inverter control uses "pulse width modulation" (PWM) or "six step" control to generate AC current wave-forms. There really are no other significantly different ways to do it.

12:10 The batteries are under the walkway, not under the aux cab. (way nit-picky on my part)

14:30 The sand boxes are only 1/4 the size that they should be. The nose cab boxes go all the way to the top where the fills are shown. Also, the rear sand fill is not on top of the radiators- maintainers could not reach that high to insert the sand fill hoses. The rear fill is actually about 6 feet above the deck…about eye level.

14:38 Most railroads do not use a 15 mph sand cutoff speed. Some have no cutoff at all. Some have different speeds depending on operating mode.

17:49 The stator exitation does not travel in reverse when the motor are in braking. It travels more slowly than rotor speed, but in the same direction.

When in motoring, it travels more quickly than rotor speed…thus "inducing" current into the induction motor. However, I will grant that for general illustrative purposes, it does kind of get the point across (but it does not accurately depict how an induction motor works)

18:18 Grids are show backwards. As shown, the super hot air would burn any person exiting the operator cab on the right side where the rear door is. Blowers should be on the right, hot air exiting on the left.

20:18 "Smart Displays" are no longer used. These are now "dumb displays" called "TCD's" (thin client displays)

24:18 There is no "Smart Display" on the helpers console. Not sure what is shown there but it could be an Auxilliary Speed Indicator (ASI) which displays locomotive speed to the Conductor.

Excellent Video! Thanks!

very nicely done.

I work in emd london ont as department manager for 31 years..ran paint shop and welding departments.. your explanation is pretty basic

wooow its amazing description, thanks lots.

Are you sure that top fans blow air down?

Excellent. Well presented and very educational.

Excellent

Dynamic braking with the resistors being cooled by fans is amazing.

The intake air gets cooling, engine gets cooling, alternator gets cooling, traction motor gets cooling, the engineer gets cooling.

This is why diesel locomotives are so cool

Every town needs one for power back up

Power the communications and water pumps

?

I like trains.

Такий собі маленький кораблик).

Great graphics. Almost completely correct information on the locomotive's operation. Just a couple very small things. I've been a locomotive engineer for 18 years and I enjoyed the video. Good work.

Thanks for the video. Now I know. Excellent work.

MY GOODNESS… These models and animations are amazing. The research is equally amazing. Wonderful work!

I live in Australia we have the longest stretch of straight level track in the world about 330km, also the longest freight trains at least a mile long, we don't have double stack trains, just long trains, one train broke down on my driveway, I offered assistance it took about 10 minutes to find a safe path around to get home haha

4 year engineer for a rail road on freight trains I have to say great video but you did get a couple things wrong there a few things I'd love to see checked and corrected on this particular model of locomotive witch looks like a ac44accte. If you the corrector of this video need info I'd be happy to help

One quick question about the air intake section. My understanding is that the engines in diesel locomotives utilize a roots blower that is driven by the engine, essentially a supercharger in addition to the turbocharger. That’s because the engines are 2 cycle diesels and need to have lots of air even at idle to force the exhaust out of the cylinder as well as a pressurized charge before compression. I may have that totally wrong but wanted to ask about that anyway. Just discovered your videos and I love each and every one of them! The detail is amazing! You have spent a lot of time in researching and in creating the graphics! Great job!!! Thank you.

make a video about computer fans 🙂

air volume , static pressure , blade design , PWM , motor voltage n watts …

Electric locomotive video